|

|||

|

|||

Norland Optical Adhesive 71 ("NOA71") is an optically clear, liquid adhesive that will cure when exposed to long wavelength ultraviolet light. The adhesive is a one-part, 100% solids material that offers advantages in bonding applications that require optical clarity or require fast cure times and long term stability over a wide range of temperatures. The use of NOA 71 eliminates premixing, drying, or heat curing operations common to other adhesive systems.

NOA 71 was formulated to provide a strong bond to glass surfaces. This adhesive can also be used for adhering to other substrates, such as metal, fiber- glass, and glass filled plastics. Typical applications are laminating solar cells, holographic plates, flat panel displays and touch screens or as a clear coating on plastic or metal.

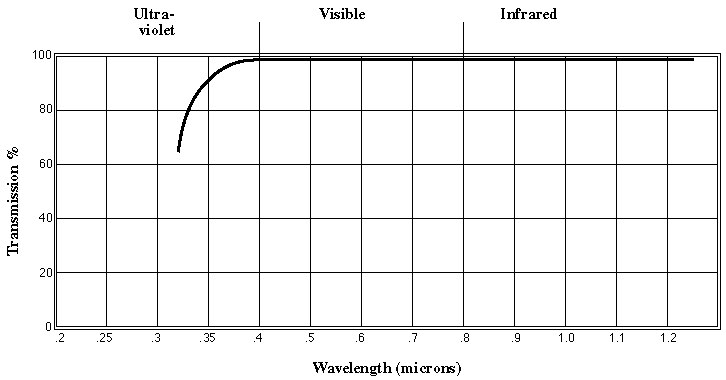

NOA 71 is cured with long wavelength UV light from 315 to 400 nanometers with peak absorption at 365 nm. The amount of energy required for full cure is 3.5 Joules/sq. cm of UV light.

| HAND HELD | MANUFACTURER | CURE AREA | APPROX. CURE TIME |

| Opticure LED 200 |

|

1/2 inch | 5-10 seconds at 1/2 inch |

| DESK TOP | MANUFACTURER | CURE AREA | APPROX. CURE TIME |

|

4 x 15 inches | 30 minutes at 6 inches |

If full cure is desired in seconds, a conveyorized light source with medium pressure mercury lamps or Fusion Systems "D"lamps must be used. Lower intensity lights such as fluorescent black lights can also be used to full cure in 10 to 15 minutes.

Uniform exposure to UV light is desirable from the beginning of cure to achieve minimal stress and strain. If this is not accomplished, separations may occur at a later date. The adhesive has linear shrinkage of approximately 1.5% and a uniform cure will allow the surface to draw closer together without creating stress.

When fully cured, NOA 71 has very good adhesion and solvent resistance but has not reached its optimum adhesion. The NOA 71 has an adhesion promoter in it that provides maximum adhesion and moisture resistance when used in glass, glass-filled or ceramic bonding applications. The adhesion promoter begins working after the cure and will provide the extra strength after 1 week at room temperature. This can be accomplished faster by warming the bonded optics to 50° C for 12 hours. The temperature range the NOA 71 bond will withstand initially is -15°C to 60° C and -100° C to 125° C after aging.

| Solids | 100% |

| Viscosity at 25° C | 200 cps |

| Refractive Index of Cured Polymer | 1.56 |

| Elongation at Failure | 43% |

| Modulus of Elasticity (psi) | 55,000 |

| Tensile Strength (psi) | 1,300 |

| Hardness - Shore D | 86 |

| Dielectric Constant (1 MHz) | 4.0 |

| Dielectric Strength (V/mil) | 456 |

Shelf life of the liquid is a minimum of 4 months from the date of shipment, refer to the package label for the actual expiration date, if stored in a cool (5-22° C), dark place in the original container. If refrigerated, allow the adhesive to come to room temperature prior to use.

Care should be taken in handling this material. The Material Safety Data Sheet should be read for this product as well as for any associated products such as alcohol, acetone or methylene chloride. Prolonged skin contact should be avoided and affected areas should be thoroughly washed with copious amounts of soap and water. If the adhesive gets into eyes, flush with water for 15 minutes and seek medical attention. Use the material in a well ventilated area, otherwise a NIOSH approved organic vapor mask is recommended.